Salvo Thread Rolls

Rolling is the most efficient method of producing threaded parts. It is faster and less expensive than cutting threads. The tool cost per part is less expensive and the rolling process is much faster. The rolled thread is approximately 30% stronger than the cut thread and is generally more consistent dimensionally than the cut thread. A thread behind a shoulder on a screw machine can not be chased and must be done secondary. However, it is possible to roll a thread behind a shoulder, as well as a thread in front of a shoulder on the same machine. The flanks of the rolled thread are burnished and will assemble easier and more quickly. Many other forms have the same advantages when rolled such as: worms, grooves, splines, knurls, ect.

Let us give you a quote. Send us a print, the machine and position that you wish to use, the type of material that you will be rolling, and any other particulars for your part and we will send you a quote.

You may contact us by Phone: 810-346-2727, Fax: 810-346-2616, or E-mail: salvo@greatlakes.net.

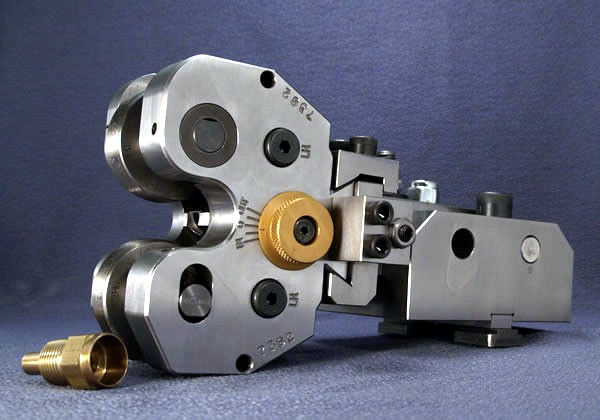

BELOW ARE EXAMPLES OF A FEW OF SALVO’S THREAD ROLLING SET-UPS:

Example of a Salvo CBL* Attachment with a #312BAR Adapter for a 9/16 or 1″ Acme Gridley Machine, shown with 3/8-18 NPTF Thread Rolls used to roll parts similar to the one shown.